We discussed the selection of filtration systems in the previous article. Fan selection is most important in ventilation when we talk about air-moving devices, selection of fan is most important because it has impact on the overall performance of the clean air system, However fan selection is difficult task, so some expert guidance is necessary. Here in this article we will discuss types of fans, some guidelines about how to choose right fan for right application? Etc..

Fans are the primary air-moving devices in industrial applications, so they have been classified into three basic groups:

Axial Fans

Axial fans are used for high flow rates at lower resistance. Axial fans are of three types:

Propeller fans are essential for general ventilation, utilizing blade types like disc or propeller blades for low resistance. Performance is sensitive to resistance, affecting flow rate.

Tube axial fans, also known as duct fans, are fans designed to move air against moderate pressures, typically with narrow or propeller-type blades in a short cylindrical housing.

Vane axial fans, typically mounted in cylindrical housings, are highly efficient and typically used in clean air applications due to their higher pressures.

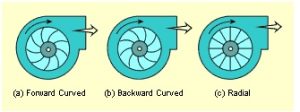

Forward Curve (Squirrel Cages):

Squirrel cages, with their low space requirements and quiet operation, are ideal for low to moderate static pressures in heating and air conditioning work but not recommended for dust or particles that could cause unbalance.

Radial Impellers:

Radial impellers offer a variety of blade shapes, ranging from high efficiency to heavy impact resistance, designed for exhaust systems. These radial blades, with medium tip speeds, handle both clean and dirty air, ensuring efficient material conveying velocities.

Backward-inclined or backward-curved impeller blades

These blades are inclined oppositely to the direction of fan rotation. These types of fans have higher speeds, efficiency, and relatively low noise levels with non-overloading horsepower characteristics.

These impellers have two types:

Special Type Fans:

Special-type fans, such as in-line centrifugal and vane axial fans, feature backward-inclined blades and similar performance curves to scroll-type centrifugal fans.

Thus, it is very important to choose the right type of fan for the right kind of application. For example, choosing a forward-curved fan for fume and dust handling will definitely be the wrong choice, as it would lead to the deposition of particles on forward-curved blades and thus imbalance.

In conclusion-

In the next article we will explore more about configurations and type of drives of fans which has a significant impact on performance of the system as a whole.

Filter On India has been working towards “Mission Zero Pollution” for the last 40+ years as a clean air solutions partner for industries. We specialize and have expertise in welding fumes, oil mist, coolant mist, dust collection, soldering, laser marking, laser cutting, plasma cutting, fumes in fastener manufacturing, ball point tip manufacturing, oil quenching, kitchen fumes, etc. Filter On has 70+ clean air solutions, so you can contact us for more information about our solutions. You can reach us through the web or visit us at our corporate office at Pune and our virtual locations at Delhi, Bangalore, Ahmadabad, Hyderabad, or Chennai locations.