Industrial air filtration and fume extraction for various industrial processes are hot topics nowadays in every industry. As fumes arise from welding, grinding, plasma cutting, laser marking, and other applications, these applications produce harmful fumes and mists, which will affect workers' health issues and productivity issues. Whether it is through an industrial welding fume extractor, an oil mist collector for CNC machines, or specialized pollution control equipment, clean air solutions are now essential for every factory. Here in this blog, we will discuss a comprehensive guide to industrial air filtration & fume extraction solutions by analyzing various applications, their fume exposures, health risks, and possible solutions.

To obtain the aforementioned advantages, you must first examine the risks of welding fumes, as well as the reasons for implementing clean air solutions more quickly. Equipment like welding fume extractors or electrostatic precipitators helps industries meet safety and environmental standards. Effective pollution control devices in industries reduce harmful emissions and improve compliance with regulations.

Dangers of Industrial Fumes and Pollutants

In the modern world, neglecting industrial air filtration and fume extraction exposes workplaces to serious risks for anyone who keep industrial environments’ air clean:

| Aspect | Benefits of Using Fume Extraction Systems | Dangers of Not Using Fume Extraction Systems |

|---|---|---|

| Employee Health | Reduces exposure to harmful pollutants, improving respiratory health | Increased risk of chronic illness, respiratory problems, and allergic reactions |

| Air Quality | Maintains clean indoor air for a safer and more comfortable workplace | Poor air quality leads to discomfort, breathing issues, and reduced concentration |

| Productivity | Healthier employees are more productive and focused | Sick workers and discomfort lower productivity and increase absenteeism |

| Equipment Longevity | Prevents fume buildup on machinery, reducing wear and tear | Fumes can corrode equipment, cause malfunctions, and increase maintenance costs |

| Regulatory Compliance | Helps meet occupational health and environmental standards | May result in violations, fines, or shutdowns for non-compliance |

| Company Reputation & Goodwill | Demonstrates corporate responsibility and care for workers and environment | Negative public image due to unsafe working conditions |

Among the special benefits of electrostatic filters are

Advantages and Features

Various sizes and configurations are available based on the demands of the application; a pressure gauge is supplied to indicate the condition of the cartridge filters.

3. Centrifugal Coolant-Imperial Mist Collectors: When water-soluble coolants are employed, mist collectors work best in all typical machining activities, such as machining centers, lathes, grinding, etc. It is also widely used in the car component sector for collecting fumes and mist from component washing and cleaning equipment. These units are a common choice in machine shops because of their easy operation, small size, and inexpensive filter replacement costs. Based on air flow capacity, Filter On provides four distinct models, ranging from 400 Cu M/hr to 2,100 Cu M/hr. Modern CNC machining centers often require a reliable oil mist collector for CNC machines to protect operators and maintain clean air quality.

In addition to these kinds, if there is limited floor space, we also provide centralized fume extraction systems with shared ducting for several purposes.

By using modern pollution reduction technology, industries can improve air quality and worker safety while reducing costs.

For the past 40+ years, Filter ON has been striving for “Mission Zero Pollution,” and we have more than 70 clean air solutions in industrial air filtration and fume extraction for the following industrial applications:

Below is a summary of the sub-applications that are part of these industrial applications.

Welding Fume Extraction: Filter ON presents various solutions in welding fume extraction. Some of the important applications we cover up here are

a) Robotic Welding Fume Extraction:

“Read our full guide here.”

b) Manual Welding Booths & SPMs:

“Read our full guide here.”

c) Portable Welding Fume Extraction:

Portable solutions like a mobile welding fume extractor are ideal for small workshops and electronics assembly lines. a drainpipe,

“Read our full guide here”

Choosing the right oil mist filters ensures long-term efficiency and minimal maintenance in industrial environments, so Filter ON, one of the best oil mist collector manufacturers, presents oil mist collection solutions for the following applications:

a) Oil Mist Collector for 5-Axis Grinding

“Read our full guide for this (coming soon).”

b) Oil Mist Collector for Gear Grinding/Hobbing Machines

“Read our full guide for this (coming soon).”

c) Oil Mist Collector for Cold Forging (Nut Bolt Mfg. Machines)

“Read our full guide for this (coming soon).”

d) Oil Mist Collector for VMCs and HMCs Coolant

“Read our full guide for this (coming soon).”

e) Oil Mist Collector for Sliding Heads

“Read our full guide for this (coming soon).

f) Oil Mist Collector for Sawing Machine

“Read our full guide for this (coming soon).”

g) Oil Mist Collector for EDM Machines

“Read our full guide for this (coming soon).

h) Oil Mist Collector for Pilger Mills

“Read our full guide for this (coming soon).”

i) Oil Mist Collector for Ballpoint Tip-Making Machines.

j) Induction Heating Application Solutions

“Read our full guide for this (coming soon).”

k) Oil Quenching Application Fume Solutions

“Read our full guide for this (coming soon).”

Filter ON presents here different dust collection solutions in gauging, laser & plasma cutting, grinding, melting & furnace,, etc.

a) Dust Collector for Laser & Plasma Cutting Machines

“Read our full guide for this (coming soon).”

b)Dust Collector for Grinding Machines

“Read our full guide for this (coming soon).”

“Read our full guide for this (coming soon).”

d) Dust Collector for Melting & Furnace Operations

“Read our full guide for this (coming soon).”

e) Downdraft Table for Dust Collection

“Read our full guide for this (coming soon).

Restaurants and industrial kitchens benefit from a dry scrubber for kitchen exhaust that removes smoke, grease, and odors effectively. In heavy-duty industries, both wet and dry scrubbers are used to manage different types of pollutants.

“Read our full guide for this (coming soon).”

“Read our full guide for this (coming soon).”

Filter ON presents here some other application solutions, such as soldering application solutions, laser marking application solutions, and induction heating application solutions. These are discussed as follows:

a) Soldering Application Solutions

“Read our full guide for this (coming soon).”

b) Laser Marking Machines Solutions

“Read our full guide for this (coming soon).”

So here Filter ON provides all these solutions to give an industry edge with its state-of-the-art electrostatic precipitation technology.

This comprehensive guide highlights why industrial air filtration and fume extraction are critical for worker health, productivity, and compliance across industries.

Ans: The Filter ON oil mist collector is one of the best oil mist collector solutions for CNC machines. Models like M02/2K DP are highly efficient at removing harmful oil mist, fumes, and smoke from machining centers. As one of the best oil mist collector manufacturers, Filter ON provides reliable industrial mist collectors, mist eliminator filters, and oil mist filters designed for high-performance CNC applications. Learn more on our website.

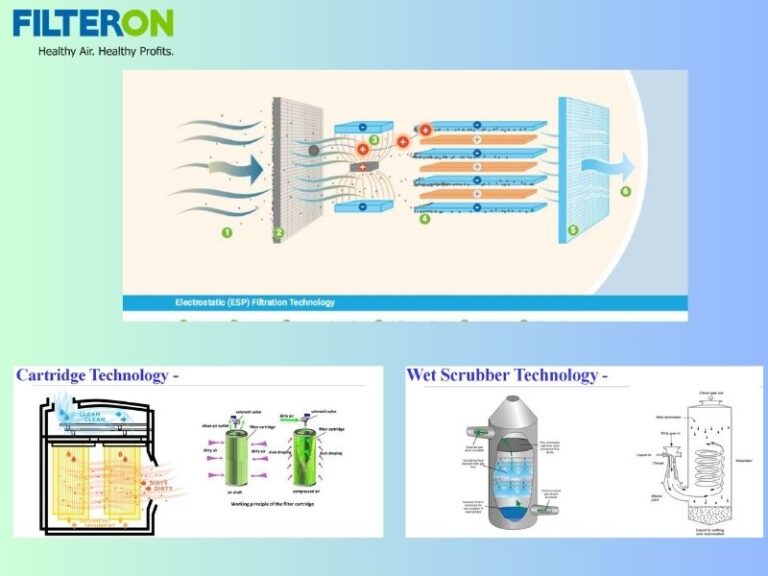

Ans: An electrostatic precipitator works by charging fine dust, smoke, and oil mist particles using high-voltage electrodes. These charged particles are then attracted to oppositely charged collection plates, effectively removing contaminants from the air. This electrostatic precipitator working principle makes it highly effective for industrial smoke extractors, oil mist collectors, and kitchen exhaust scrubbers.

Ans: Dry scrubbers use absorbent materials or sorbents to capture pollutants, while wet scrubbers spray liquids to wash contaminants out of the air. In industries like food, chemical, and manufacturing, both dry and wet scrubbers are widely used. A dry scrubber for kitchen exhaust is preferred where water handling is a challenge, while wet-dry scrubbers are used in heavy industries with high particulate matter.

Ans: Welding produces harmful fumes containing metals, gases, and particulates that can damage workers’ health. A welding fume extractor or industrial welding fume extractor prevents inhalation risks, improves workplace safety, and ensures compliance with industrial safety standards. Many welding fume extractor manufacturers also provide fume extractor accessories like fume extractor filters and fume extractor pipes for better performance.

Ans:Portable welding fume extractors, or mobile welding fume extractors, provide flexibility to capture fumes directly at the source, especially in confined spaces or field jobs. These portable smoke extractors with fume extractor filters act as mobile air-cleaning systems, ensuring clean air wherever welding takes place.

Ans: Kitchen exhaust scrubbers are essential in restaurants, hotels, food-processing plants, and industrial kitchens. A dry scrubber for kitchen exhaust or a scrubber for kitchen exhaust removes grease, smoke, and odors to maintain hygiene and meet local pollution norms.

Ans: Common electrostatic precipitator uses include controlling air pollution in power plants, steel plants, cement factories, chemical industries, and commercial kitchens. Their ability to remove fine particulates, oil mist, and fumes makes them ideal pollution control equipment for multiple industries.

Ans: The industrial fume extractor price depends on factors like capacity, filtration technology, and brand. Basic portable fume extractors are cost-effective, while high-capacity industrial fume extractors and Kemper welding fume extractors may cost more. Contacting leading fume extractor manufacturers ensures the best price-to-performance ratio.

Ans: The efficiency of an electrostatic precipitator can reach up to 99%, making it more effective than many conventional fume extractor filters. Unlike mechanical filters, ESPs require less frequent replacement, making them a cost-efficient choice in the long run.

Ans: Without an oil mist collector for CNC machines, operators are exposed to harmful aerosols that can cause respiratory issues and slippery floors. Contaminated air also damages sensitive machine components. Using a filtermist mist collector, oil mist filters, or electrostatic oil mist collector ensures both worker safety and longer machine life.

Ans: Yes. While Losma mist collectors and Kemper fume extractors are well-known, Filter ON offers customized fume & mist collectors with advanced industrial filtration equipment. Our products often outperform competitors in terms of durability, filter life, and maintenance cost.

Ans: Pollution control devices in industries, such as scrubber and electrostatic precipitator systems, fume smoke extractors, and dust & fume collectors, help reduce emissions and meet environmental regulations. These pollution control solutions also protect employees, improve workplace safety, and enhance corporate sustainability efforts.

To know more about fume extraction standards and regulations, please check here.

Contact us at marketing@filter-on.com.