Robotic welding fume extractors are essential components of modern manufacturing. Robotic welding fumes are extremely hazardous for workers in industries such as automotive components and material handling, where automated welding lines are common.

Since these welding lines operate continuously, it is crucial to mitigate the risks and protect workers. In this blog post, we’ll discuss how robotic welding fume extractors work, why they’re important for maintaining clean air in industrial environments, and how Filter ON can help.

Let’s get started!

Introduction to Robotic Welding Fumes

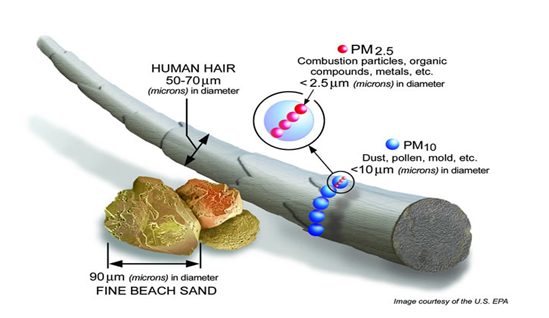

Robotic welding fumes vary in composition and can seriously harm workers who operate or maintain robotic welding cells. These fumes contain pollutants such as PM2.5 and PM10, which are dangerous when inhaled over time.

How robotic welding fumes generated?

Robotic Welding fumes are generated rapidly you can check and see in this below video for clarification, This shows how robotic welding fumes are generated

Potential Danger Due to Robotic Welding fumes:

In industrial workplaces, inadequate air filtration and fume extraction pose significant health risks, including respiratory diseases and chronic illnesses. Workers exposed to fumes without proper systems, like a Robotic welding fume extractor, are vulnerable to conditions such as bronchitis and cancer, which negatively affect their morale and well-being. Poor air quality can also lead to discomfort, decreased concentration, and productivity loss. Furthermore, industrial fumes can damage equipment, increase maintenance costs, and trigger non-compliance with health regulations, which impairs a company's reputation and environmental responsibility. Effective solutions like Robotic welding fume extractors are essential for maintaining air quality and ensuring worker safety. Learn more about potential danger due to Robotic Welding Fumes in our Comprehensive Guide to Industrial Air Filtration.

Even though robotic welding is automated, it continuously generates fumes.

- Robots work without breaks, so fumes accumulate rapidly.

- Welding cells whether open or closed allow fumes to spread quickly. In open setups, they can contaminate the entire workspace.

- Without proper filtration or exhaust systems, air quality deteriorates, productivity drops, and workers’ health suffers.

How Does a Robotic Welding Fume Extraction System Work?

Robotic fume extractors operate based on the volume of generated fumes and the rate of clean air output. Two main extraction methods are used:

1. Source Capture Method

In this method, a suction arm captures fumes directly from the welding source.

Portable extraction systems are ideal for large welding jobs where welders move around frequently.

2. Ambient Extraction Method

Here, stationary fume extraction systems with canopies, hoods, and ducting are used. They capture fumes from the entire robotic welding cell and filter them through a central system.

Common Pollutants in Robotic Welding Extractions

Robotic welding fumes contain various pollutants such as metal fumes, ozone, and gases.

- Metal Fumes: These include fine particles (PM2.5 and PM10) that are highly hazardous to human health. Robotic welding fume extractors are essential to remove them.

- Ozone and Other Gases: Ozone and other gases formed during welding can cause eye irritation and respiratory problems. Fume extraction is necessary to remove these as well.

Learn more about industrial pollutants in our Comprehensive Guide to Industrial Air Filtration.

Key Components of a Robotic Fume Extraction System

A robotic fume extraction setup typically includes:

Clean air system (ESP system)

Filters

Hoods and canopies

Ducts

Blower unit

Electrical panel

Hoods and Canopies

These structures capture fumes precisely to prevent exposure and health risks.

Ducting

Carries fumes from the welding area to the filtration system.

Filters

The most critical component — filters remove harmful smoke and fine particles.

Suction Hood

Draws in fumes using a blower motor. The size depends on the type of welding machine or setup.

Blower or Motor

Generates the suction force required for fume capture.

Electrical Panel

Controls and monitors the extraction system.

ESP Stacks

Electrostatic Precipitator (ESP) stacks use ionization to capture and remove fine particles efficiently.

Role of Electrostatic Precipitators (ESP) in Robotic Welding Fume Extraction:

An ESP filtration system cleans air containing welding fumes, smoke, and fine dust.

How it works:

Fume Collection: Polluted air is drawn from the robotic welding cell.

Electrostatic Charging: The air passes through an electrostatic field, charging the particles.

Particle Removal: Charged particles adhere to oppositely charged plates, removing even submicron particles (as small as 0.01 µm).

Clean Air Output: Fresh air is released back into the workshop or outside.

Easy Maintenance: Washable metallic filters mean no frequent replacements and low operating costs.

Efficiency: ESPs are highly effective and maintain a clean, safe working environment.

Benefits of Robotic Welding Fume Extraction:

- Improved Air Quality & Worker Safety

Clean air reduces breathing problems, eye irritation, and other health risks improving overall productivity. - Better Equipment Performance & Reduced Downtime

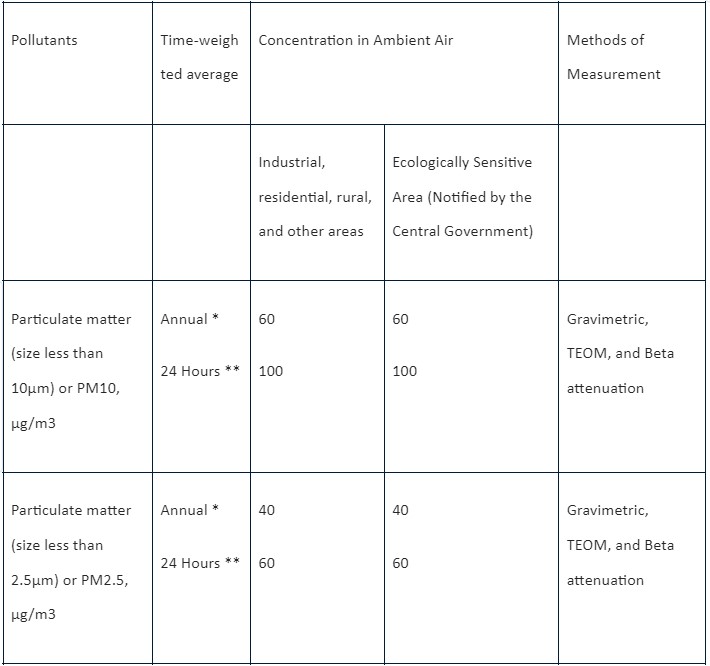

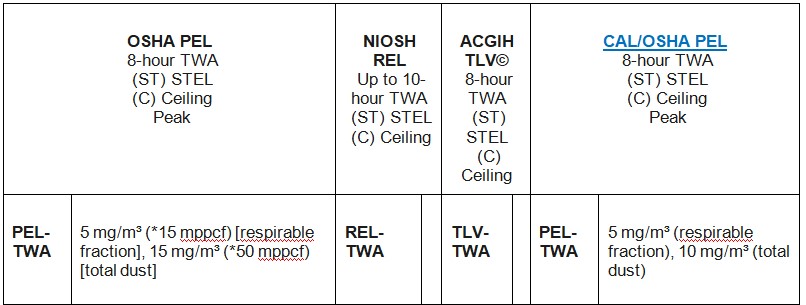

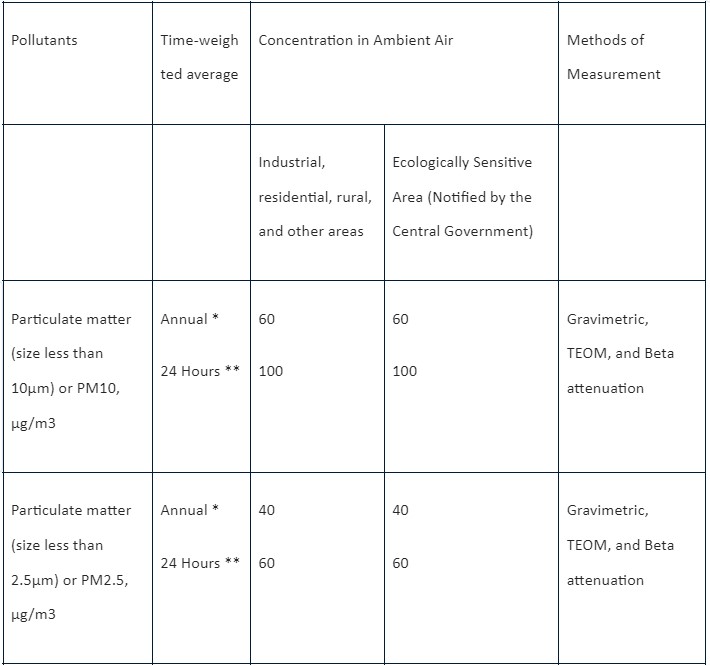

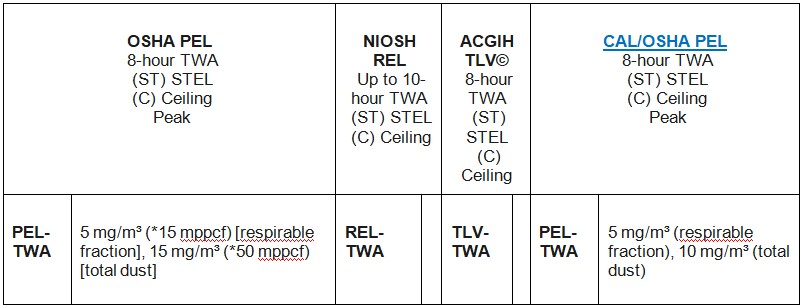

Washable ESP filters reduce maintenance needs, keeping systems running smoothly. - Compliance with Safety Standards

Systems must comply with OSHA and CPCB standards.

Read more about Fume Extraction Standards & Regulations

Choosing the Right Extraction System

Selecting the right extraction system ensures worker safety and operational efficiency. Consider:

- Air Volume: Determines the size and capacity of the system.

- Robot Layout: Open or closed cell designs require different solutions.

- Type of Welding: MIG, TIG, laser, or plasma welding all produce different fume levels.

Centralized vs. Individual Extraction Units

- Centralized Systems: Ideal for large plants with multiple robotic welding cells.

- Individual Units: Offer flexibility and source-level fume capture.

Smart Controls and Automation Integration

Modern fume extraction systems feature smart controls, such as remote monitoring, automatic shutoff, and real-time alerts. Ensure these features are considered when selecting your system.

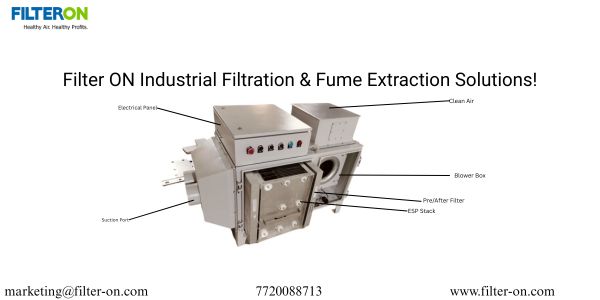

Filter ON’s Solutions for Robotic Welding

Filter ON is a leading Indian provider of industrial air filtration and fume extraction systems, working toward “Mission Zero Pollution” for over 40 years.

We offer over 70 clean air solutions across welding, oil mist, dust collection, and kitchen scrubber applications. For robotic welding, they provide both individual and centralized ESP-based systems.

Why ESP-Based Systems Are Ideal for Robotic Welding

Compared to cartridge filters, ESP systems offer major advantages:

- Zero filter replacement cost

- Lower power consumption

- Higher filtration efficiency

- Washable filters for long-term use

Filter ON’s ESP-based systems deliver proven results for both individual and centralized setups.

Custom Design and After-Sales Support

Every plant has unique requirements. Filter ON provides custom-designed solutions backed by decades of experience and strong after-sales support, ensuring reliable system performance.

Conclusion

ESP-based robotic welding fume extractors offer high efficiency, low maintenance, and long-term value. With over 40 years of expertise, Filter ON continues to deliver innovative, customized, and sustainable clean air solutions for industries across India.

Contact Filter ON at marketing@filter-on.com to design a robotic welding fume extraction system customized for your factory setup.