Understanding Sulphur Dioxide(SO2):Sources Of Pollution, Health Impact, Knowing Safety Limits and Solutions.

Sulphur Dioxide (SO2) is one of the most significant primary air pollutants after carbon dioxide and nitrogen oxides. This harmful gas plays a major role in industrial air pollution and poses serious risks to workers’ health and workplace safety. In this article, we explore how SO2 becomes a threat in industrial environments, its health impact on workers, the safety limits required to control SO2 exposure, and the key government regulations designed to reduce the risks associated with Sulphur Dioxide in industries.

What is sulfur dioxide(SO2)?

Sulfur dioxide (SO2) is a colorless, toxic gas with a strong, choking odor. It's a member of the sulfur oxide (SOX) family of chemicals, which are made up of sulfur and oxygen.

Sulfur Dioxide (SO2) as a Pollutant

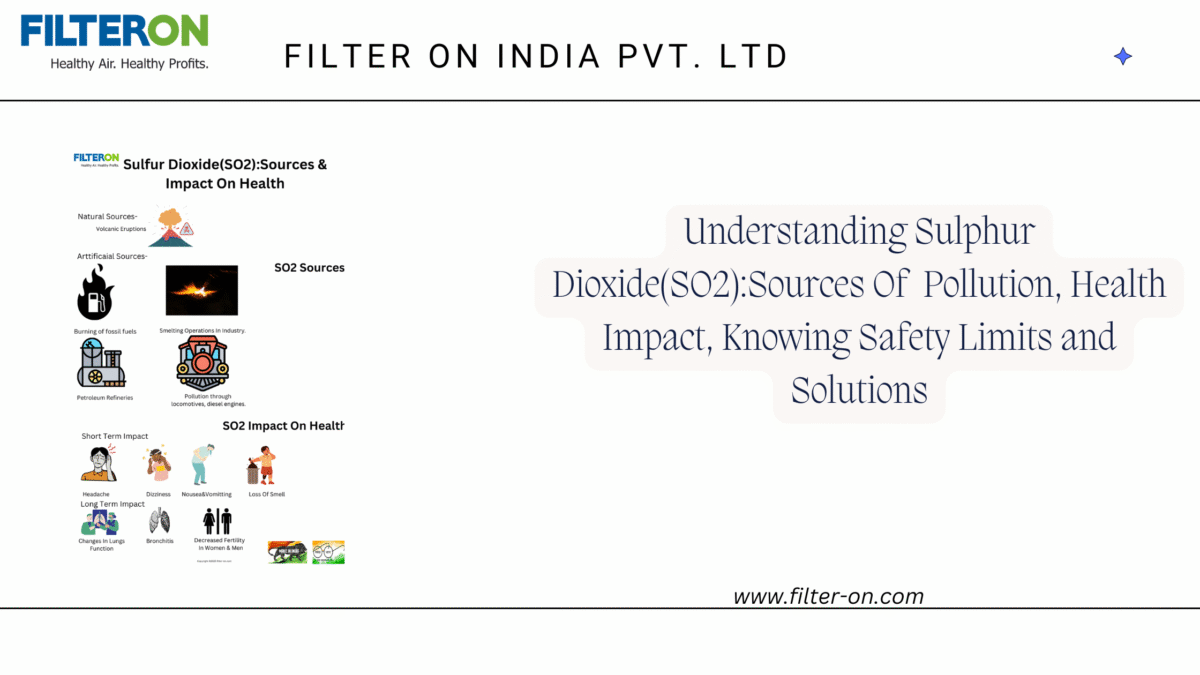

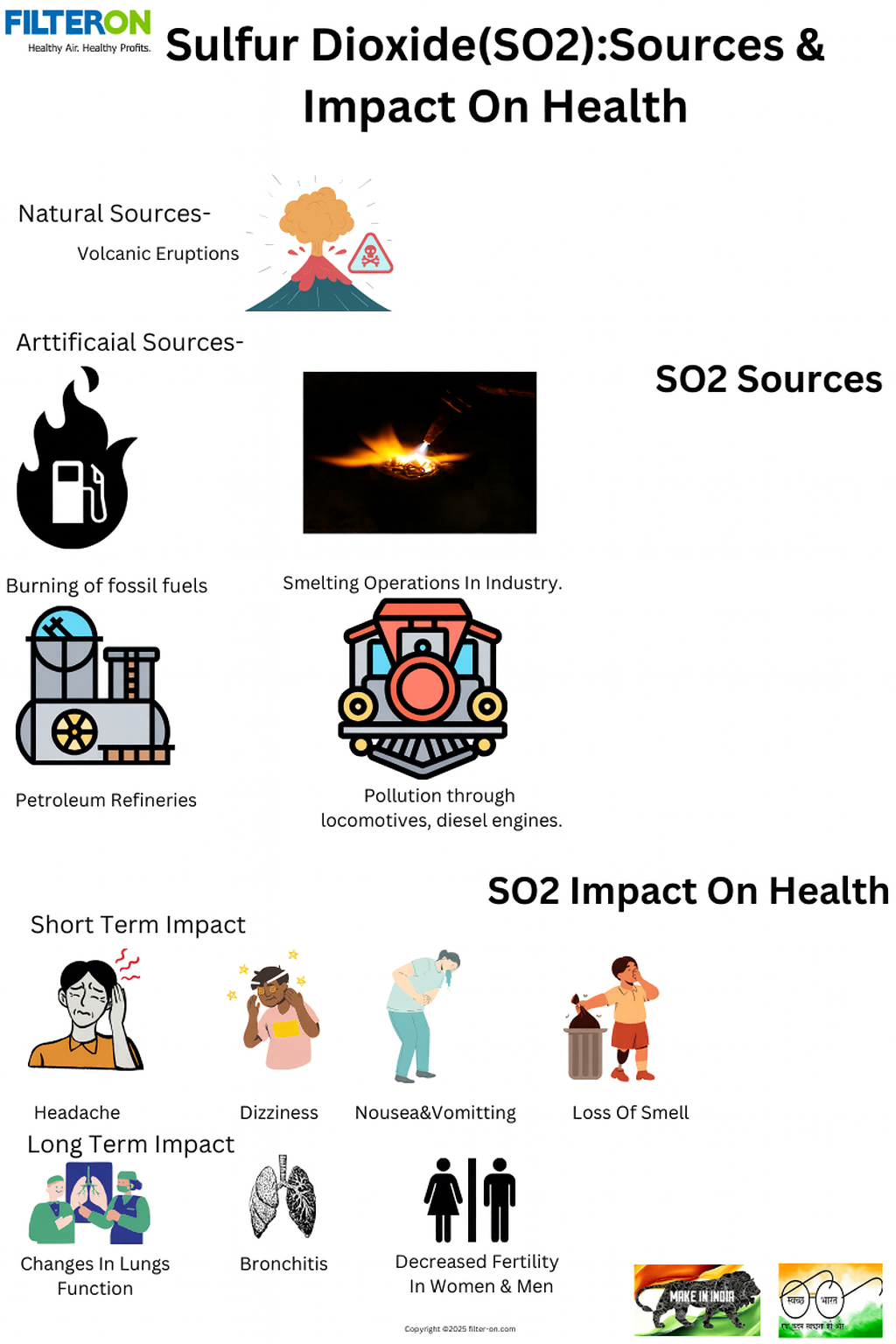

Sulfur dioxide has various sources of pollution; some of the sources are as follows:

Natural Sources

Sulfur dioxide is naturally generated through

Volcanic Eruptions

Artificial Sources

There are two types of artificial sources of SO2.

- Industrial Sources

- Other Sources

In industries, SO2 is generated through petroleum refineries, cement manufacturing, paper pulp manufacturing, and metal smelting and processing facilities.

Other sources of SO2 include locomotives, large ships, and some non-road diesel equipment that currently burns high-sulfur fuel and releases sulfur dioxide into the air.

Burning fossil fuels (coal and oil) for domestic heating is also a source of SO2

Highest Concentration Of SO2 In The World –

In the world scenario the highest concentration of SO2 is from our country India, then on the second spot is Russia and Third is China.:

India as the largest emitter of SO2 in the world, contributing more than 21% of global emissions mainly coming from coal-based electricity generation.

How are you exposed to Sulphur dioxide(SO2)?

You can be exposed to Sulphur dioxide(SO2) by breathing it in the air or getting it on your skin. People who live near industrial sources of sulfur dioxide may be exposed to it in the air. You are most likely to be exposed if you work in industries where SO2 is produced, such as copper smelting or power plants, or where it is used in the production of sulfuric acid, paper, food preservatives, or fertilizers. People with malfunctioning appliances or chimneys in their homes may also be exposed to sulfur dioxide.

Most SO2 exposures are caused by people breathing contaminated outdoor air.

SO2 Impact on Health:

The impact of SO2 on health consists of short-term and long-term impacts.

Short-Term Impact of SO2 on Health:

Exposure from breathing sulfur dioxide can cause:

- Burning of the nose, throat, and lungs

- Difficulty breathing

- Loss of smell

- Headaches and dizziness

- Nausea and vomiting

- Harm to the respiratory system: As an irritant, sulfur dioxide can affect lung function and cause and worsen respiratory diseases in humans and animals.

Exposure to very high levels of sulfur dioxide can be life-threatening.

Touching liquid sulfur dioxide can cause:

- Frostbite

- Irritation of the eyes:

Long-Term Impact of SO2 on Health:

Long-term exposure to sulfur dioxide can cause:

- Changes in lung function

SO2 emissions that lead to high concentrations of SO2 in the air generally also lead to the formation of other sulfur oxides (SOx). SOx can react with other compounds in the atmosphere to form small particles. These particles contribute to particulate matter (PM) pollution. Small particles may penetrate deeply into the lungs, and in sufficient quantity, they can contribute to health problems.

- Bronchitis and shortness of breath

People with asthma may be sensitive to changes in respiratory effects due to SO2 exposure at even low concentrations. Sulfur dioxide is not classified as a human carcinogen (it has not been shown to cause cancer in humans).

- Decreased fertility in women and men:

Continuous inhalation of SO2 affects fertility rates in women and men.

Solutions for SO2 Exposure at Industries

Safety measures taken by industries Include the following:

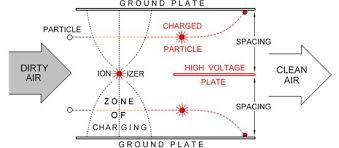

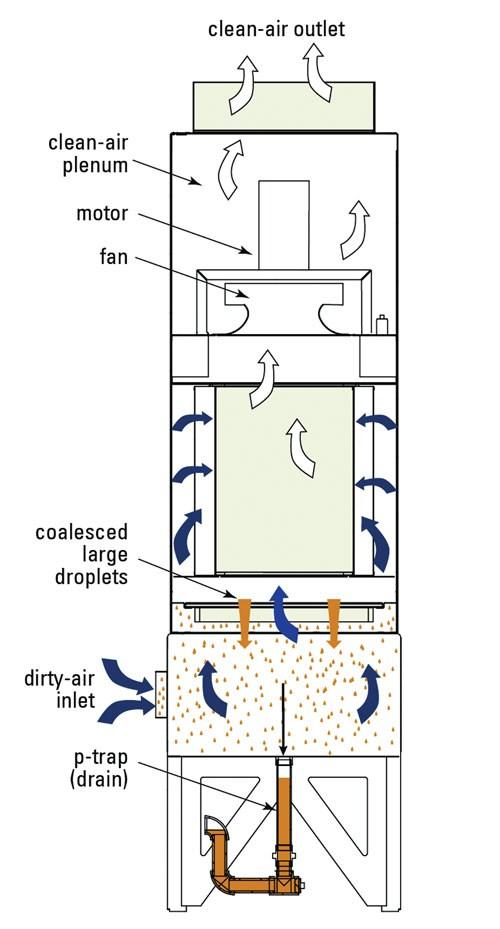

Use ventilation systems.

Use of ventilation systems like LEV (local exhaust ventilation) can reduce the exposure to SO2 to some extent, which leads to an increase in air flow capacity in the work environment, which is very important for workers health.

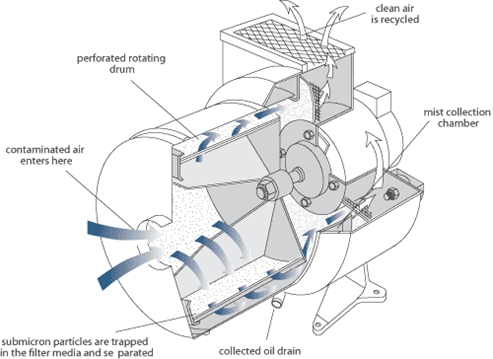

Use of Extraction Systems:

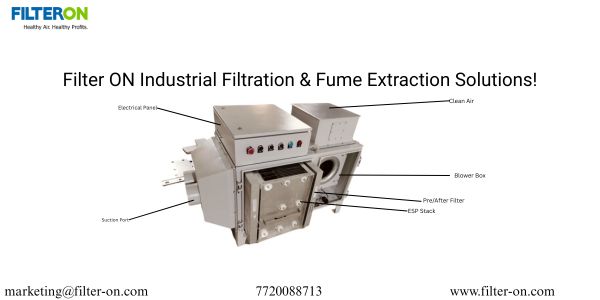

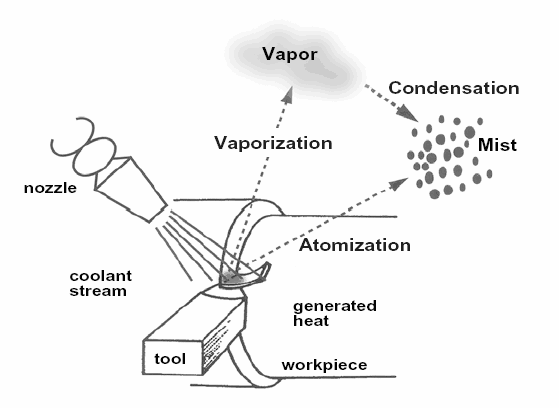

Using extraction systems for air pollution control is the best solution to protect workers from high exposure to SO2-like pollutants, such as Filter On welding fume extraction systems, oil mist collectors, and dust collection systems will be very beneficial for industries to reduce the risk of SO2-like pollutants on workers health.

Use the government guidelines.

Using and following the government guidelines from time to time will surely reduce the exposure of SO2 in industries, and it will have a positive impact on society.

Here are some safety precautions for SO2 exposure, including:

- Using personal protective equipment as required

- Increasing ventilation in the area or moving a leaking container to a well-ventilated and secure area

- Stopping or reducing the leak if it is safe to do so

- Knocking down gas with fog or a fine water spray

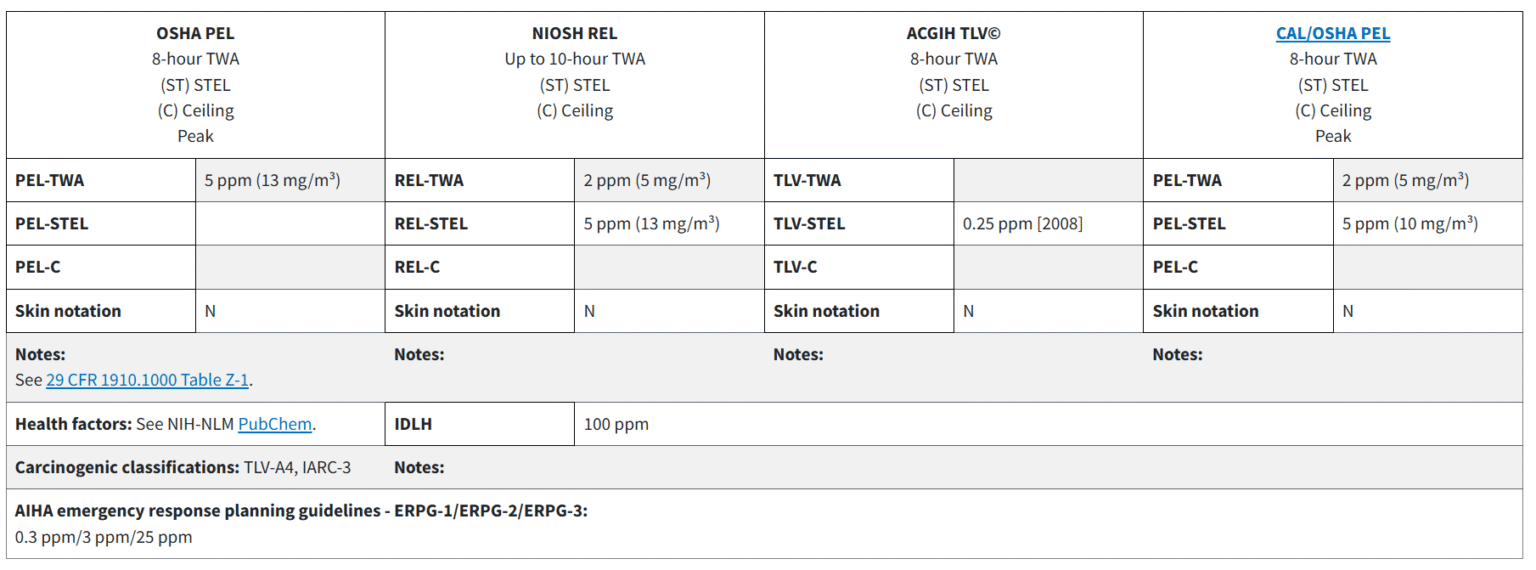

Safety limits for SO2 exposure.

As per OSHA, the permissible safety limits for SO2 exposure are as follows:

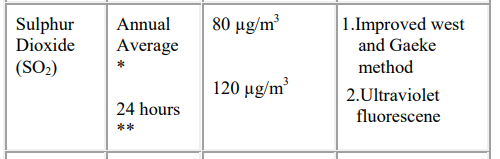

In India, as per CPCB-Central Pollution Control Board Of Regulation the SO2 Exposure limits are as follows-

Visit blogs to learn more about the critical features of clean air system design and air pollution control systems created by Filter On India.